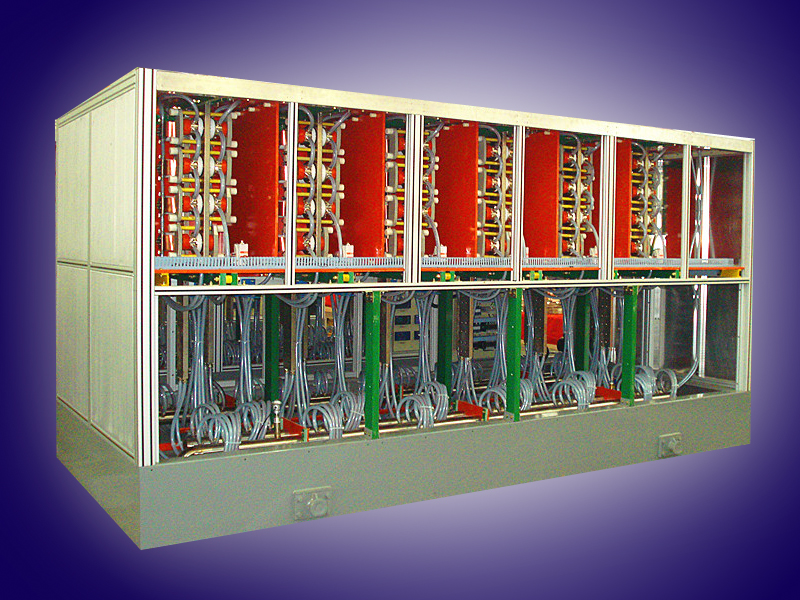

ZE (H) S Series of High-power and Hierarchical Diode Rectifier

Product performance: Rectifier Cabinet with Brand New Structure not only possesses the strengthes of that which is not noninverting and inverse parallel structure, but also has some new technical features, this structure meets the new requirements of rectifying means in the electrolytic aluminum industry (high level of series of voltage) and makes up defects of some traditional vertical structures (noninverting and inverse parallel structure). Its safety coefficient is much higher than that of noninverting and inverse parallel structure, low failure rate and convenient maintenance. It will not occur the phenomena of positive and negative arcing by misplacedly arranging the positive and negative rectified groups, completely separating with insulating materiais and forming two completely separate units. Arms of two noninverting elements with the same polarity are fixed on the same element row by adopting wafer-installed manner, forming two combined bridge arms. By doing this, the previous rectified arms can be reduced from 12 to 6, using a spring steel and steel briquetting to press symmetrically; the average current of elements is good. The screw of mounting element, a special insulating and composite screw, cuts off the magnetic circuit of element crimper; The frame of cabinet is assembled by special aluminum to avoid heat generating, its structure is much more innovative and beautiful and effects of magnetic isolation have increased substantially.

DC output parameters: voltage ≤1580V, current (single cabinet) ≤60kA.

Structural features: high security, low noise, good effects of average current, high-voltage, low electrical corrosion, simple waterway, convenient maintenance and aesthetic appearance.

Application: High-power electrolytic DC power (aluminum, magnesium electrolysis, salt electrolysis, electric furnace of graphite, electric furnace of silicon carbide, other metal electrolyses and similar loads).